Application Tips for Series 700

Contrinex 12th Dec 2022

Comparison with standard devices

Compared to standard inductive proximity switches, Condet devices feature numerous advantages, in particular:

- The devices are built into a one-piece, stainless-steel housing (sensing face included) and, as a result, are extremely robust as well as absolutely impervious at the front.

- They achieve very long operating distances on steel.

- Similarly long operating distances are also obtained on non-ferrous metals (aluminum, brass etc.).

Even though Condet devices are inductive proximity switches, their way of functioning, as described in detail in the Contrinex technical note no. 9 "Condet Proximity Switches", differs from that of conventional executions. In consequence, their detection properties are only the same at first glance. Closer examination, however, shows a few differences that could be important, depending on the application. These differences are only partially apparent from the data sheets. A detailed examination, with no claim to completeness, is presented below. Attention to these points will help to take optimum advantage of the new devices, and to avoid problems and failures.

Target influence

Target material

In principle, Condet devices give approximately the same operating distances on non-ferrous metals as on steel (with standard devices, an important reduction must be reckoned with on non-ferrous metals). The correction factor is, however, not exactly 1 (table 1). It is, moreover, dependent on the device's size, execution (embeddable I non-embeddable) and the target geometry (dimensions and thickness). Consequently, it is not possible to give data for all conceivable cases in this paper. However, the devices are factory adjusted so that, using a standard target (according to IEC I EN 60947-5-2), they have the same operating distance on both steel and aluminum.

Metal Correction factor (Table 1a)

for M12 embeddable

Steel (FE 360) 1.00

Aluminum 1.00

Brass 1.30

Zinc 1.15

Magnesium 1.05

Titanium 0.90

Copper 0.85

Stainless steel (1.4301) 0.45

Metal Correction factor (Table 1b *no detection)

for M30 non-embeddable

Steel (FE 360) 1.00

Aluminum 1.00

Brass 1.20

Zinc 1.10

Magnesium 1.25

Titanium 0.00*

Copper 0.85

Stainless steel (1.4301) 0.00*

Stainless steel is a special case. Because of its low magnetic permeability and high specific electrical resistance, the depth of penetration for the alternating magnetic field generated by the proximity switch is relatively high. It is, incidentally, this property that makes the use of a closed stainless-steel housing possible. In practice, this means that the operating distance on this material is considerably influenced by its thickness (see below). Although the term stainless steel encompasses a great variety of alloys, the behavior of all non-magnetic variants is very similar. High penetration depths are also observed with other metals and alloys; however, these are of negligible technical importance.

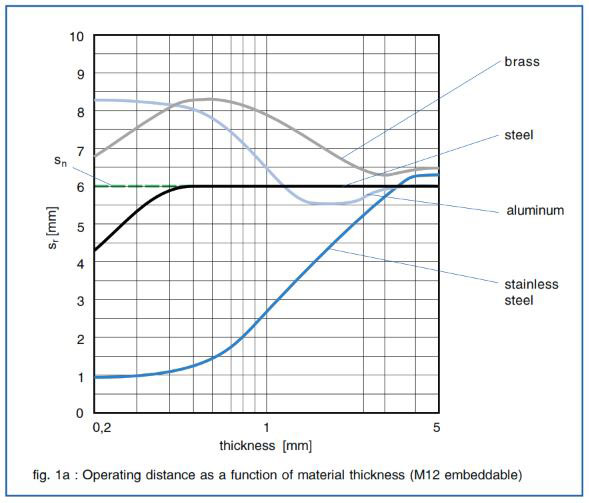

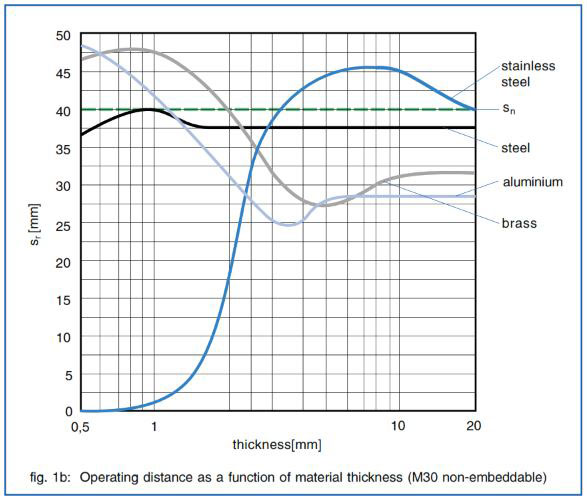

Target thickness

The sensing behavior of conventional standard inductive devices is only slightly influenced by the thickness of the target. Foils, in particular those of aluminum, are an exception. In comparison to thicker objects, they produce a much higher (2 to 3 times) operating distance. Condet devices, on the other hand, behave differently. As a rule of thumb, the operating distance for a material thickness of over about 1 mm remains constant for the metals (stainless steel excepted) generally used in machine construction. Below 1 mm, it decreases. Foils, as a rule, cannot be detected. In the case of stainless steel, a much greater material thickness must be reckoned with in order to achieve the full operating distance (fig. 1). Additionally, the behavior is dependent on the device diameter (because of the various working frequencies), and on the execution (embeddable I non-embeddable). This property of stainless steel can be used to advantage (see next section but one).

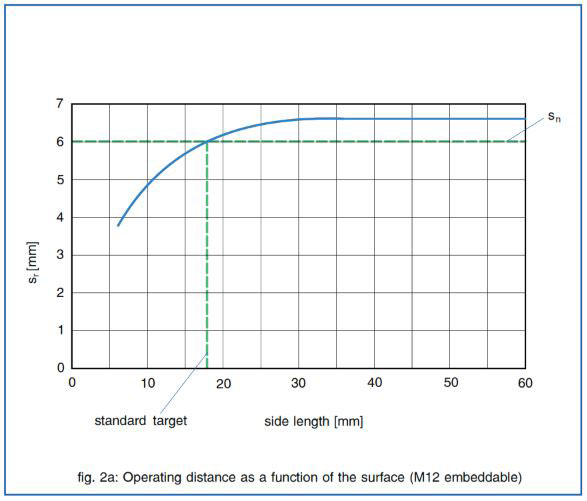

Target dimensions

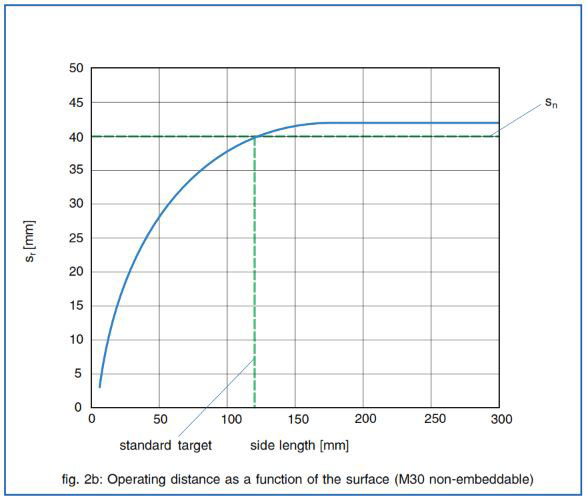

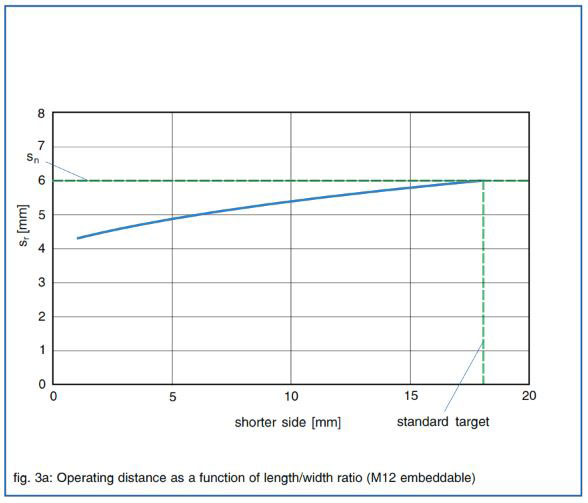

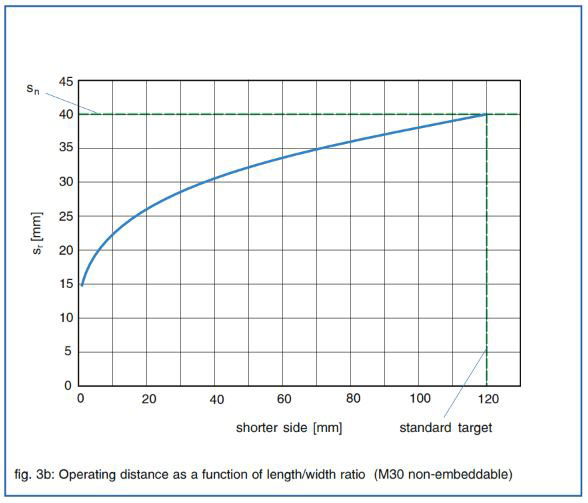

Condet proximity switches are outstanding for the detection of flat objects (fig. 2). The angle of the surface to the device is not particularly important. The operating distances with rod-like objects or wires are, in comparison, lower (fig. 3). In such cases, devices using Condist technology give far better results.

Detection through metal walls

The relatively high penetration depth of the field generated by Condet oscillators can be used to advantage. In effect, it permits the detection of metallic objects through metal walls (fig. 4). With its high penetration depth, stainless steel is best. However, with the necessary precautions, detection is also possible through other metals. There are no generally valid rules for the choice of the most suitable type of proximity switch, or for the dimensions of the wall and target. The best configuration must be determined from case to case by trials, for which Contrinex will gladly provide help.

Mounting

Surrounding metals

Mounting of the embeddable execution is not at all critical, and scarcely differs from the procedure with conventional devices. However, the usual free spaces must, of course, be respected. On the other hand, with non-embeddable versions, the considerably greater tendency to be influenced by non-ferrous metals must be considered. Contrary to standard devices, this is roughly the same as that of steel. It should further be noted that, due to the technology used, the zone of influence extends further back and over a wider diameter than usual, although the maximum values are strictly maintained according to the standard. With large, non-embeddable devices especially, it is important to pay proper attention to the necessary free spaces.

These minimum free spaces are given in the data sheets and the instruction leaflets accompanying the products. The distances to be respected with non-embeddable devices of large diameters are considerable in comparison to standard devices. However, use can be made of the fact that these distances are material dependent (see information on the data sheets of the respective devices).

Fixing

The fixing of Condet proximity switches is basically the same as for standard devices. With non-embeddable devices, especially size M30, the aptitude of the device to be influenced by the fixation parts should be borne in mind (see above, "Surrounding metals"). The use of plastic fixing clamps, commonly found in the market (picture 2 - also obtainable from Contrinex), is an effective possibility in this case. It is further recommended to pay attention to the choice of fixing nuts. The influence of the stainless steel nuts delivered with the device is much smaller than that of brass or steel nuts. This can lead to problems, since the visual distinction between stainless-steel and nickel or chrome-plated surfaces is not easy to make, even for professionals.

Alignment

As with all proximity switches, in order to avoid mutual interference, a minimum distance must be maintained between neighboring devices. These are given in the data sheets. Compared to standard devices, due to the technology used, these are larger with Condet proximity switches. It should further be observed that for axially opposed devices, a relatively large distance is necessary.

The devices react normally, even if the distances are too small, but the switching edges are irregular (flutter). Nevertheless, objects can be detected without problem, provided that this fluttering does not interfere or can be filtered by software. There are various possibilities to reduce this mutual interference. The most important of these are described in the Contrinex technical note no. 6, "Tips for Mounting Inductive Proximity Switches". In addition, shielding can be employed.

Magnetic fields

All inductive proximity switches are disturbed by external alternating magnetic fields whose frequencies lie close to the device's operating frequency. Contrary to standard proximity switches, whose operating frequencies lie in the region of a few 100 kHz, Condet devices work in the region of a few kHz. Consequently, the potential to be influenced differs.

Experience shows that, in particular, 50 Hz magnetic fields with a high harmonics content, such as stray fields from mains transformers as well as nearby stepping motors can lead to problems with Condet devices. On the other hand, the potential to be influenced by switching power supplies, induction heaters etc. is markedly lower. Permanent magnetic fields and low frequency alternating fields (50 / 60 Hz) with low harmonics content are permissible up to a field strength of 1,000 A/m (size M30: 80 A/m).

Liquids

Thanks to their one-piece stainless steel housing (picture 3), Condet proximity switches are by nature particularly suitable for use in environments where liquids are present. The chemical resistance of stainless steel itself sets the limits, except for the connection side, where attention has to be paid. With cable executions, impermeability is excellent from the construction point of view, but the chemical resistance of the plastics used (PBTP, PUR) can set limits. With connector versions, this is evidently also the case, but in addition, there is a further critical point over which the proximity switch manufacturer has no control: the junction between the connector and the device. A missing or unsuitably dimensioned O-ring on the connector side, or a notch in the connection area on the device side, can considerably interfere with sealing. It is thus recommended to use cable versions in applications where sealing is critical.

EMC

Condet proximity switches meet all EMC requirements according to EN 60947-5-2 and the standards mentioned therein. They are thus also usable in heavily disturbed industrial environments without problem. It should merely be observed that in comparison to standard devices, they behave differently with respect to magnetic frequencies in the range of their operating frequencies (see above "Magnetic fields").

12th Dec 2022