Inductive Sensor Product Range

Contrinex 12th Dec 2022

PRODUCT RANGES - BASIC

First choice in all environments

Contrinex Basic range inductive sensors have a worldwide and well-deserved reputation for uncompromising accuracy and exceptional reliability. With best-in-class sensing distances between 1.5 mm and 40 mm, the Basic range offers fit-and-forget operation, delivering world-class performance and a highly attractive total cost of ownership. Available in sizes from M8 to M30 and C44, with optional Ø 6.5 plain and 8 mm square-section models, Basic range inductive sensors are ideal for general position-sensing and presence-sensing applications in almost any industry. Embeddable or non-embeddable variants are available, with either hard-wired, hermetically sealed connecting cables or integral metal connectors. Basic range devices, whether from the Classics (Fig. 1), Extra Distance (Fig. 2) or Full Inox (Fig. 4) technology families, all utilize Contrinex application-specific integrated circuits (ASICs) that ensure highly repeatable results at operating temperatures between -25°C and +70°C. An IO-Link interface is also available for communication in PNP NO versions.

MINIATURE

Full functionality, smallest size

Size is often a critical constraint when selecting sensors for position or presence sensing. The Contrinex Miniature range, which includes the smallest self-contained inductive sensors on the market, meets this constraint without compromising on functionality.

Sensors from this range use either Classics (Fig. 1), Extra Distance (Fig. 2) or Full Inox (Fig. 4) technology. Available in plain and threaded sizes from Ø 3 to M5 and as a 5 mm square-section type, Miniature range inductive sensors are ideal for applications where space is limited, including tool-selection, robotic position-sensing and control of micro-mechanisms.

Extremely robust, thanks to chip-scale package (CSP) technology, a glass-fiber reinforced substrate and vacuum encapsulation, the Contrinex Miniature range delivers long-term reliability and maximum uptime, even in the most demanding environments. The low mass and high switching frequency of these sensors makes them particularly suitable for high-dynamic applications where inertia is a major consideration.

These embeddable devices are available in 3-wire DC, NPN and PNP versions with a choice of NO or NC configurations. An LED output state indicator is standard. All the important protection functions are included, such as short-circuit and overload protection, full polarity reversal protection, induction protection, EMC protection, power-on reset, etc. With a sensing range up to 3 mm, Contrinex miniature inductive sensors combine world-class quality with a highly attractive total cost of ownership. An IO-Link interface is also available for communication in PNP NO versions.

EXTREME

Extreme durability in harsh environments

Only the toughest sensors survive the most extreme environments, and Extreme range inductive sensors from the Full Inox family are ideally equipped for the job. Thanks to one-piece stainless-steel (V2A/ AISI 303) construction and a hermetically sealed cable entry, Extreme sensors are corrosion-resistant, impervious to oil, and pressure-resistant to 100 bar. Rugged, reliable and highly accurate, the Extreme range is at home in the most challenging circumstances.

Developed to withstand the harshest industrial operating conditions, Extreme sensors are rated to IP 68 and IP 69K, delivering fit-and-forget performance with minimal downtime. With operating distances up to 40 mm, the Extreme range senses both ferrous and non-ferrous materials with Factor 1 performance, and is available in sizes from M8 to M30 and C23. An IO-Link interface is also available for communication in PNP NO versions.

ANALOG OUTPUT

Continuous analog output for precision control

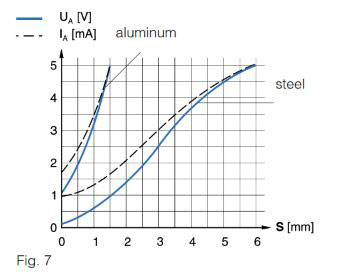

Engineers needing a reliable, repeatable, highly accurate means of measuring the position of a target object should look no further than Contrinex Analog Output inductive sensors. This range of sensors has been developed on the platform of Extra Distance (Fig. 2) technology for excellent temperature stability, repeat accuracy, and the best long-range sensing capability on the market. With a measurement range of zero to 40 mm and detection accuracy on the micron scale, the Analog Output sensor range is ideally suited for measuring linear, angular and rotational position (Fig. 7). They offer world-class performance and an attractive total cost of ownership in applications from vibration monitoring and end-position approach regulation, to position monitoring, metal sorting and sheet-metal forming.

Analog Output inductive sensors are available in sizes from M8 to M30, with the option of an 8 mm square-section model. Voltage outputs are included for all sizes, while sizes M12 and above feature both voltage and current outputs.

2-WIRE

Easy installation and high switching frequency

The 2-Wire range of DC, AC/DC and NAMUR sensors is constructed on the Classics (Fig. 1) technology platform and includes sizes from Ø 3 to M30, plus a 5 x 5 mm square-section type. Devices are available for embeddable or non-embeddable mounting and connection is by means of cable or connector. With a sensing range up to 15 mm, Contrinex 2-Wire sensors ensure optimal equipment utilization.

EXTRA PRESSURE

Pressure resistant up to 200 bar

Dependable, accurate presence and position sensing at pressures up to 200 bar requires world-class performance and build quality. The Extra Pressure range of pressure-resistant inductive sensors delivers exactly that, operating continuously in permanently pressurized conditions. This makes the range especially suitable for offshore installations, the chemical industry, motor lubrication systems and atomic fuel element monitoring. A stainless-steel housing with bonded ceramic or brazed sapphire sensing face and protection class IP 68 guarantees robustness and exceptional reliability in miniature packages sized from Ø 3 to Ø 6.5.

The Extra Pressure range is also ideal for high-vacuum environments and satellite applications, offering fit-and-forget capability and a sealed cable-entry that ensures no loss of service or interruptions to production.

Sensors from this range use either Classics (Fig. 1) or Extra Distance (Fig. 2) technology and have equivalent electrical properties. For optimum impermeability, LED and connector versions are not available in this range.

Sensors from the Extra Pressure range detect parts at sensing distances up to 2.5 mm, and offer a highly attractive total cost of ownership. An IO-Link interface is also available for communication in PNP NO versions.

HIGH PRESSURE

Resistant to pressure and dynamic stress up to 500 bar (peak 1000 bar)

For reliable, accurate sensing in the most demanding pneumatic and hydraulic applications, Contrinex offers a unique range of High Pressure sensors with permanent operating pressures of 100 ... 500 bar and peak pressures up to 1000 bar.

Suitable for operating temperatures up to 100°C and resistant to more than 1 million pressure cycles, their IP 68 and IP 69K protection and oil impermeability make them the robust, reliable choice for the hydraulic industry. Fit-and-forget operation virtually eliminates sensor replacement costs. Exceptional performance and world-class quality are assured in sizes from M5 to M18.

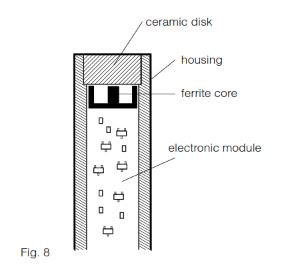

Contrinex High Pressure sensors are available in either Extra Distance (Fig. 2) or Full Inox (Fig 4) versions. Both of these technologies ensure durability without compromising on usable operating distance. Sensor construction is simple and robust, with the whole electronic unit, ferrite core and coil included, safely on the no-pressure side. Sealed connection is by means of either flexible PU cable or an integral connector.

Fig. 8 shows an Extra Distance version. The stainless steel housing is heat shrunk onto the ceramic disk, making the sensor mechanically resistant, exceptionally impervious, and outstanding for applications with high dynamic pressure stress, such as piston-control applications. With operating distances of up to 3 mm, they are gas-tight and meet protection class IP 68.

Versions from the Full Inox family have a practically indestructible pressure and corrosion-resistant one-piece stainless steel housing (V4A / AISI 316L / DIN 1.4404). They provide excellent detection of all metals with good conductivity, both ferromagnetic and non-ferromagnetic. These corrosion resistant sensors are suitable for the harshest conditions and meet protection classes IP 68 & IP 69K. An IO-Link interface is also available for communication in PNP NO versions.

EXTRA TEMPERATURE

Temperature resistant up to 120°C

Inductive sensors from the Extra Temperature range offer the ideal solution for position and presence-sensing applications at temperatures from as low as minus 40°C up to 120°C. Industrial processes often generate heat, resulting in temperatures that would damage a standard sensor, but the stainless-steel construction and robust electronics of Contrinex Extra Temperature sensors ensure reliable, accurate operation and minimal downtime, even in the most demanding environments.

Sensors from this range use either conventional Classics (Fig. 1) or all-metal Full Inox (Fig. 4) technology. Individually compensated for repeatable, highly accurate operation across the full operating temperature range, Extra Temperature inductive sensors accommodate sensing distances up to 25 mm, minimizing the risk of collision damage.

Available in sizes from M5 to M18, the Extra Temperature range delivers best-in-class performance at elevated temperatures in the harsh environments of the automotive, molding and metal-processing industries. An IO-Link interface is also available for communication in PNP NO versions.

HIGH TEMPERATURE

Temperature resistant up to 180°C (230°C with external amplifier)

Contrinex High Temperature inductive sensors are designed for continuous operation at temperatures from 0°C up to 180°C (up to 230°C with remote electronics). The range is ideal for the harshest environments, including automotive paint shops, metal-treatment plants and glass manufacturing.

High Temperature sensors use Classics (Fig. 1) technology. Embeddable, non-embeddable and quasi-embeddable versions are available. For temperatures up to 180°C, sensors feature built-in amplifiers and include highly durable 100 % silicone-free types. Connection is by means of an FEP, Teflon or silicone cable. For 230°C types, the amplifiers are built into an M12 stainless-steel housing, which is connected by means of a standard 3 m Teflon cable, and thus removed from the hot area. Stainless steel construction and sensing distances up to 25 mm minimize the risk of mechanical damage during operation, ensuring maximum plant availability and a highly attractive total cost of ownership. Contrinex High Temperature sensors are available in sizes from M8 to M50.

WELD-IMMUNE

Immune to magnetic fields and resistant to weld spatter

Contrinex Weld-immune inductive sensors are ideal for the hostile working environments found in automotive factories and other industrial welding plants. The range includes sensors from two technology platforms: Classics (Fig. 1) and Full Inox (Fig. 4).

Classics devices, with protection class IP 67, are available either in PTFE-coated cylindrical brass housings or a PBTP 40 x 40 mm cubic form. They resist solder and the strong magnetic fields present during industrial welding processes. They have identical operating distances on steel and non-ferrous metals.

Weld-immune sensors built on the Full Inox platform have a long operating distance and Factor 1 on steel and aluminum. One-piece, stainless-steel (V2A / AISI 303) construction makes these sensors the most durable on the market, ensuring minimal down-time. These practically indestructible sensors withstand the welding environment for years, resisting electromagnetic fields, welding spatter, cleaning and impacts.

All Weld-immune sensors are embeddable and have an integral S12 connector. Best-in-class sensing ranges of up to 15 mm eliminate the risk of collision - a frequent hazard when operating in close proximity to moving machine parts.

Developed for extreme accuracy throughout the welding cycle, Weld-immune sensors continuously detect part presence and machine position to ensure optimal equipment utilization and prevent errors in production. These sensors provide excellent repeatability at temperatures between -25°C and +70°C.

CHIP-IMMUNE

For the harshest machining environments

Even when covered with chips of steel, stainless steel, aluminum, brass, copper or titanium, Chip-Immune inductive sensors from the Full Inox technology family will reliably detect targets made of these metals. The sensors achieve this with a slightly modified form of Condet technology.

In a one-piece stainless steel housing with IP 68/IP 69K protection rating and a wide operating temperature range from -25 to +85°C (-13 to +185°F), they are particularly suitable for use in the harsh environments of the machining industry. Depending on sensor diameter (M12, M18 or M30), operating distances of 3, 5 or 12 mm are available. In the PNP version, sensors also include an IO-Link interface for point-to-point communication with the controller of the system.

DOUBLE-SHEET

Detection of double-sheets in metalworking

For double-sheet detection, sensors from the Full Inox (Fig. 4) family are used. Its patented inductive technology enables discrimination between one and two conductive metal sheets of a defined thickness, achieving sensitivity of 0.8 - 1.2 mm per sheet. This discrimination aids in the prevention of double feeds into blanking and forming processes which ultimately saves damage to tooling. The one-piece, stainless-steel construction of these sensors makes them the most durable on the market. They withstand the impacts that are a common hazard in double-sheet detection applications close to moving sheet metal, ensuring minimal down-time.

INTRODUCTION

MARITIME

DNV-GL approved for ships, ports and offshore

The Maritime range of embeddable inductive sensors, certified by Germanischer Lloyd, offers unrivalled performance features based on Full Inox technology (Fig. 4). With a one-piece housing in V4A/AISI 316L stainless steel and an enclosure rating of IP

68/IP 69K, they are not only impervious, but also corrosion-proof and resistant to salt water. Their EMC protection also meets specific maritime requirements, particularly with regard to power supply variations and low frequency immunity. They offer the longest service life of any inductive sensor on the market, even in the harshest marine environments. The maximum operating pressure is 80 bar or 500 bar (peak 800 bar) for P12G high-pressure types. Depending on sensor size (M12, C23, M18 or M30), operating distances of 6, 7, 10 or 20 mm are available. In the PNP version, sensors also include an IO-Link interface for point-to-point communication with the controller of the system. The range also includes M10 types with Classics technology.

WASHDOWN

Ecolab approved for strictest production hygiene

Washdown inductive sensors are certified to operate continuously and reliably in the harsh conditions of the food, beverage and pharmaceutical industries, ensuring uninterrupted production. With Ecolab approval and rated to IP 68 and IP 69K, they are pressure resistant up to 80 bar, food safe and corrosion resistant.

Washdown sensors are available in conventional Classics (Fig. 1) technology, size M12, or Full Inox (Fig. 4) technology, sizes M12, M18 and M30. Full Inox types have a totally impervious one-piece housing in stainless-steel (V4A / AISI 316L), including the sensing face. They are therefore highly resistant to the corrosive chemicals used for clean-in-place or wash-down processes. With Factor 1 on steel and aluminum and extended sensing ranges up to 40 mm, Full Inox technology minimizes the possibility of impact damage - a common hazard in confined operating spaces.

Washdown sensors meet the increasingly demanding sensing needs of the food, beverage and pharmaceutical industries, delivering best-in-class performance with an attractive total cost of ownership. An IO-Link interface is also available for communication in PNP NO versions.

Conversion of temperature

Celsius Fahrenheit

-40 -40

-25 -13

0 +32

+70 +158

+85 +185

+100 +212

+120 +248

+180 +356

+230 +446

Conversion of pressure

Bar PSI

1 14.5

80 1160

100 1451

200 2901

500 7255

800 11603

1000 14510

12th Dec 2022