RFID Product Range

Contrinex 12th Dec 2022

RFID (Radio Frequency IDentification) is used in numerous automation and logistics domains. It allows objects to be identified by means of electronic labels (transponders or tags).

Compared to classic systems, such as bar codes or laser marking, RFID technology offers important advantages. Transponder information can be read or written even when there is no direct line of sight between it and the Read/Write Module. In addition, information can be added, modified or replaced. It is a useful technology for automated production, reducing human error while increasing reliability, flexibility and traceability.

ConIdent (also called ConID) is the general name of the Contrinex RFID system, including transponders, Read/Write Modules and interfaces in both low frequency (LF) and high frequency (HF) technology.

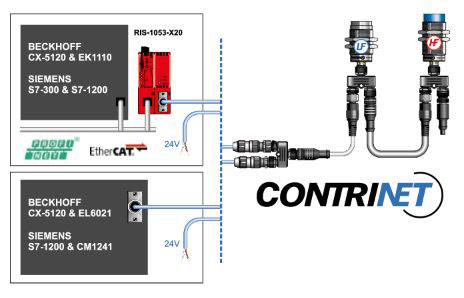

ContriNET is the product name of the Contrinex RFID network and protocol. The ContriNET protocol uses an RS485 physical layer, which allows LF and/or HF Read/ Write Modules to be daisy-chained, reducing the total number of interfaces.

- Up to 10 ContriNET RWMs with one USB interface

- Up to 31 ContriNET RWMs with one industrial bus interface

- Up to 254 ContriNET RWMs on a half-duplex RS485 interface

While the usual interfaces allow connection of a limited number of Read/Write Modules (typically 4), ContriNET RWMs can be used to reduce the number of interfaces, which makes the cost of a ConID system more economic than solutions proposed by the competitors. In principle, a ContriNET network can extend to a length of 200 m. An RFID system always has the structure illustrated on page 371.

TECHNOLOGY

LOW FREQUENCY (LF) RFID (31.25 KHZ)

Contrinex LF RFID technology features not only conventional plastic components, but also a range of all-metal Read/Write Modules and transponders in stainless steel. These devices are particularly suitable for difficult operating environments where they will be exposed to cleaning, harsh chemicals, water and frost. They are also highly resistant to mechanical shocks.

- Non-standard technology (proprietary data communication)

- Reads and writes through metal

- Works in a metallic environment (fully embeddable)

- High resistance in harsh environments

- Very high temperature tags (VHT 180°C / 356°F) embeddable in metal

HIGH FREQUENCY (HF) RFID (13.56 MHZ)

Contrinex HF RFID technology complies with ISO/IEC 15693 and is therefore open to any components that meet this standard. HF systems allow fast communication between transponders and Read/Write Modules as well as extended functionality for tag data protection.

- ISO/IEC 15693

- Anti-collision, in case of multiple tag detection

- Very high temperature tags (VHT 180°C / 356°F) embeddable in metal

- Ultra high temperature tags (UHT 250°C / 482°F)

RFID COMPONENTS

TRANSPONDERS (TAGS)

A transponder is an electronic product that stores data. Transponder memory includes a unique preset number as an identifier and a memory area for writing user application data in relation to tagged product information. Writeable data may include, for example, the object’s history or the parameters of operations to which it will be subjected.

READ/WRITE MODULES (RWMS)

A Read/Write Module is a device that allows data to be read from or written to a transponder.

INTERFACES

An interface connects the Read/Write Modules to an industrial fieldbus. ConID interfaces are available for PROFIBUS, DeviceNet, EtherNet/IP, PROFINET, EtherCAT, POWERLINK, Ethernet TCP/IP and USB.

Communication between the RWM and any tags is provided by the modulation of a carrier frequency.

PRODUCT FAMILIES

BASIC

Contrinex Basic RFID components are ideal for general identification and monitoring tasks in almost any industry. The family includes low and high-frequency passive, plastic transponders (tags) and threaded Read/Write Modules (RWMs). All devices are insensitive to dirt. HF components (13.56 MHZ) are fully ISO/ IEC 15693-compliant, while LF components (31.25 kHz) utilize a proprietary data communication protocol. If the ContriNET protocol is used, LF and HF components can share one network, including the full range of interfaces.

LF Basic tags are embeddable and available in diameters of 20 mm, 30 mm and 50 mm. Maximum read/write distances when used with Basic M30 RWMs range from 25 mm to 41 mm. Housings have an IP67 enclosure rating and are temperature resistant from -40 ... +125°C (-40 to +257°F). LF Basic RWMs are non-embeddable and, when used with a 50 mm Basic tag, offer maximum read/write distances of 37 mm for the M18 type and 41 mm for the M30 type.

HF Basic tags are non-embeddable and available in diameters from 9 mm to 50 mm. Maximum read/write distances when used with Basic M30 RWMs range from

14 mm to 60 mm. Housings have an IP67 enclosure rating and are temperature resistant from -40 ... +125°C (-40 to +257°F). HF Basic RWMs are non-embeddable and, when used with a 50 mm Basic tag, offer maximum read/write distances of 42 mm for the M18 type and 60 mm for the M30 type.

EXTREME

The Extreme family of metal, low-frequency components is particularly suitable for use in harsh environments, such as the steel industry, agriculture and other outdoor applications. It comprises stainless-steel (V2A / AISI 304) passive tags and threaded RWMs that utilize proprietary LF data communication (31.25 kHz). All components are insensitive to dirt and designed for outstanding performance in metallic environments. If the ContriNET protocol is used, these LF components can share one network with HF types, including the full range of interfaces.

LF Extreme tags are readable/writable through metal and available in diameters of 10 mm, 16 mm, 26 mm, M16 and M30. Mounting is fully embeddable, including in metal, and maximum read/ write distances when used with Extreme M30 RWMs range from 4 mm to 13 mm. Housings have an IP68 enclosure rating and are temperature resistant from -40... +95°C (-40 to +203°F). In addition, a non-embeddable M30 type is also available with a maximum read/write distance of 12 mm and an IP68 & IP69K enclosure rating. LF Extreme RWMs are non-embeddable and, when used with a 26 mm Extreme tag, offer maximum read/ write distances of 12 mm for the M18 type and 13 mm for the M30 type. They have an IP68 & IP69K enclosure rating.

WASHDOWN

The Washdown family of full-metal, low-frequency components has been designed for demanding wash-in-place applications within the food, pharmaceutical and other industries. Passive tags from this family offer the highest mechanical and chemical resistance, being fully sealed, laser welded and made of food-grade stainless steel (V4A / AISI 316L). As a result, they are highly corrosion-proof, saltwater resistant and withstand aggressive solvents.

With an enclosure rating of IP68 & IP69K, Washdown components resist high-pressure cleaning and function reliably in water. They have also been optimized for a wide operating temperature range: -40 to +125°C (-40 to +257°F). If the ContriNET protocol is used, LF RWMs can share one network with HF types, including the full range of interfaces.

LF Washdown tags are readable/writable through metal, insensitive to dirt and available in diameters of 10 mm, 16 mm, 26 mm, M16 and M30. Mounting is fully embeddable, including in metal, and maximum read/write distances when used with Washdown M30 RWMs range from 4 mm to 13 mm. In addition, a non-embeddable M30 tag is also available with a maximum read/write distance of 12 mm.

LF Washdown RWMs are non-embeddable and, when used with a 26 mm Washdown tag, offer maximum read/write distances of 12 mm for the M18 type and 13 mm for the M30 type.

HIGH TEMPERATURE

With 100 % silicone-free construction and thermal cycling reliability of 1000 hours (or 1000 cycles), passive tags from the High Temperature family are ideal for use in paintshops and other high temperature environments. Tags are insensitive to dirt and their housings have an IP68 & IP69K enclosure rating. HF tags (13.56 MHZ) are fully ISO/IEC 15693-compliant, while LF tags (31.25 kHz) utilize proprietary data communication.

LF High Temperature, embeddable tags are suitable for the range -40 ... +180°C (-40 to +356°F). Thanks to full-metal, stainless-steel (V4A / AISI 316L) housings, they are food safe, corrosion-proof and can withstand aggressive solvents. Tag diameter is 26 mm and, when used with a Basic M30 LF RWM, the maximum read/write distance is 26 mm.

HF High Temperature tags offer the highest temperature resistance with a range of non-embeddable, silicone-free LCP types for temperatures from -25 ... +250°C (-13 to +482°F). Based on EEPROM or FRAM technology, memory size ranges from 128 Bytes to 2048 Bytes. Tag diameter is 50 mm and, when used with a Basic M30 HF RWM, the maximum read/write distance is 60 mm. Life expectancy is exceptionally long, even under intense read/write and temperature cycling.

For temperatures in the range -25 ... +180°C (-13 to +356°F), a PPS type is also available. With a diameter of 26 mm, this HF tag is suitable for embeddable mounting in metal. The maximum read/write distance with a Basic M30 RWM is 31 mm.

The IO-Link family of high frequency read/write modules (HF RWMs) with IO-Link interface V 1.1 has been designed for easy, cost-effective integration into existing control systems.

These non-embeddable HF RWMs are available in sizes M18 and M30. When used with a 50 mm diameter tag, they offer maximum read/write distances of 42 mm for the M18 type and 60 mm for the M30 type. They can be operated either as IO-Link devices or in standard I/O mode (SIO) with conditional binary outputs. In stand-alone SIO mode the conditional output switch enables either tag detection or data block comparison.

With two operating modes and simplified plug-and-play installation, these HF RWMs reduce installation costs, typically in the logistics, mechanical engineering and automotive industries.

USB

The USB family of low and high-frequency read/write modules (RWMs) is ideal for user access control stations and tag programming by PC. USB RWMs are robust, economical and easy to mount thanks to standard threaded housings. Available in four sizes (M18/M30 x 35 mm and M18/M30 x 50 mm), they offer read/write distances up to 60 mm with a tag diameter of 50 mm. HF RWMs (13.56 MHZ) are fully ISO/ IEC 15693-compliant, while LF RWMs (31.25 kHz) utilize proprietary data communication. Host communication relies on the hexadecimal-based ContriNET protocol, which allows LF and HF RWMs to use the same demo software as standard (Basic) ContriNET RWMs. Drivers are available for Windows XP, 7, 10, CE4 & CE5 operating systems.

SUPPORT TOOLS

For each product, a dedicated package of all the necessary support tools (software, firmware, drivers, DLL files, 3D-CAD models, etc.) can be downloaded from the relevant product-finder page on the Contrinex website.

APPLICATIONS

WASHING STATIONS

In the harsh environment of a washing station, RFID transponders and Read/Write Modules (RWMs) are exposed to hot water, mechanical shocks, corrosive chemicals and high-pressure jetting. Despite these challenges, identification systems must operate continuously with high reliability. Typically, RFID tags are mounted on the part carriers. On arrival at the washing station, information from the tag is used to select the correct washing cycle for the part type and process.

LF Washdown advantages

ConIdent Washdown passive tags require no power source, minimal maintenance and function reliably in water. Designed to withstand high pressure cleaning and aggressive solvents, their rugged, full-metal, laser welded housings are fully sealed against water penetration (IP 68 or IP 69K) and withstand temperatures up to 125°C (+257°F). Their extended sensing range reduces the risk of mechanical damage. RWMs that withstand pressure washing are also available.

MACHINE TOOLS

The presence under pressure of lubricating and cooling fluids, combined with metal particles, makes the machine tool environment particularly difficult. Identification components must resist fluid penetration to prevent machine downtime and ensure the RFID system reliability.

An industrial network of Read/Write Modules (RWMs), interfaces and tags forms a complete RFID system to control the path of each workpiece through all machining cycles, programming and logging every step.

LF Extreme advantages

Components from the ConIdent Extreme family offer outstanding performance in metallic environments. All-metal tags and RWMs are insensitive to dirt and resistant to corrosion, impact and abrasion. When embedded in metal, they are impervious with an IP68 & IP69K enclosure rating. Tags are optimized for operating temperatures from -40 to +95°C (-40 to +203°F) and RWMs, which utilize proprietary data communication (31.25 kHz), are not influenced by the presence of metal particles.

TESTING LINES

Product testing lines may comprise several test stations, each performing a fixed sequence of tests. For efficient real-time monitoring, identification systems must integrate well into the overall control system.

In a typical RFID system, part carriers are equipped with tags and every test station has a Read/Write Module (RWM). To program the testing machine, the RWM reads from each tag the type of test required for an individual part. After each test, the RWM writes the results back into the appropriate tag memory address/location. Test reports are automatically forwarded to the controller for product acceptance or rejection and fault correction.

HF Basic advantages

ConIdent HF Basic tags and RWMs are fully compatible with ISO/IEC 15693, with fast data transfer times and a comprehensive range of interfaces for the widest fieldbus coverage on the market. Thanks to user-defined password protection features, data security is also excellent.

HF Basic RWMs use the powerful ContriNET protocol, which allows LF and HF RWMs to be daisy-chained on the same network. The HF RFID system also includes IO-Link and USB families. IO-Link RWMs allow easy system integration and USB RWMs enable direct connection to a PC.

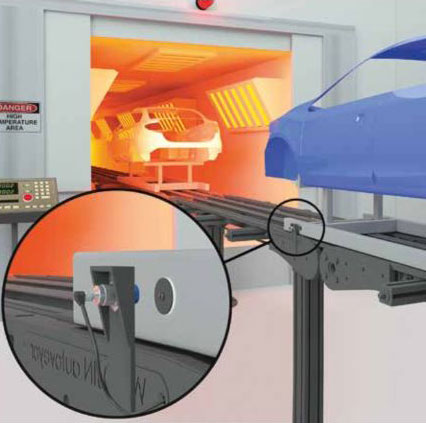

PAINT SHOPS

Identification components in paint shops are exposed to a variety of rinsing, coating and burning operations, including electrophoresis. Since soiling makes visual identification difficult or impossible, rugged RFID systems are an excellent solution.

The RFID tag accompanies each product throughout all painting processes. It can store individual data, including customer requirements, directly on the product or carrier. This allows highly automated customized processes, with smaller batches and central data storage.

HF High Temperature advantages

The ConIdent High Temperature family includes 100 % silicone-free tags that are ideal for paint-shop applications. Life expectancy is exceptionally long, even under intense read/write and temperature cycling.

- Tag RTP-0263-020, for embedded or non-embedded mounting in metal; Ø 26 mm (1.02”), temperature resistant up to 180°C (356°F)

- Tag RTP-0502-022, RTP-0502-062, RTP-0502-082, non-embeddable; Ø 50 mm (1.97”), temperature resistant up to 250°C (482°F) and 100 % silicone-free

12th Dec 2022