What Is An AC Drive?

AC drives are also known as Inverters, Variable Speed Drives (VSDs), Variable Frequency Drives (VFDs) and frequency converters. AC Drives are used to control AC Induction motors; the most common motor technology used in industry. The motors are rugged, require very little maintenance and can easily be manufactured with high environmental protection.

AC drives are also known as Inverters, Variable Speed Drives (VSDs), Variable Frequency Drives (VFDs) and frequency converters. AC Drives are used to control AC Induction motors; the most common motor technology used in industry. The motors are rugged, require very little maintenance and can easily be manufactured with high environmental protection.

If an AC motor is connected directly to the mains supply the motor will accelerate quickly and then rotate a fixed speed which is dependent upon the electrical supply frequency and the motor design. For some applications fixed speed is acceptable and, by carefully selecting gearbox ratios, a desired final output speed can be achieved. However, for most applications, hard acceleration, unbraked deceleration and the inability to vary the speed and torque represent a serious problem.

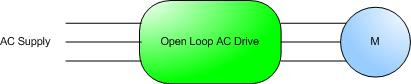

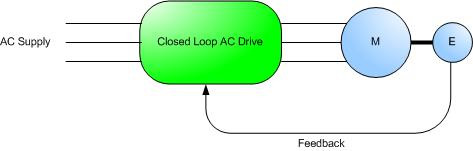

Lenze Drives provide a solution by modifying the voltage and frequency of the AC supply to the motor. Control is achieved by either estimating the motor speed, known as open loop control, or by measuring the speed, known as closed loop control. Both techniques have advantages and disadvantages:

Open Loop Control

Open loop control provides the simplest means of controlling AC induction motors, as the speed of the motor is dependent upon the frequency of the supply, a basic means of control is simply to vary the voltage and frequency to achieve the desired motor speed. This method is known as V/Hz control. The major disadvantages of this method of control are poor precision and poor low speed torque.

A huge amount of research has been undertaken to improve the open loop performance of Lenze AC Tech Drives. Open Loop Vector and Direct Torque Control technologies attempt to model the motor in real time to compensate for a wide range of factors that affect the speed and torque delivered at the output shaft. The result of these methods is a large performance and accuracy improvement, however, at low speed performance may still be a problem. Rotor Flux Control (RFC) is a new method of control for open loop drives which offers improved stability and greater dynamic performance.

Open loop drives are used where the motor is never required to hold a load at zero or low speed, and where the torque and speed accuracy are not important, typical applications include:

- Pumps

- Fans

- Conveyors

- Mixers

- Centrifuges

Closed Loop Control

Closed loop control is achieved by using a speed and position sensor connected to the motor shaft.

The result is stable, accurate, dynamic speed and torque control from standstill through to maximum speed.

Typical application include:

- Cranes and hoists

- Lifts

- Winding

- Material handling

- Automotive testing

- Extruding

Intelligent Drives

Lenze Group's AC Tech is the market leader in intelligent drives; this refers to drives that have programmable automation or motion controllers within the product as standard or as an option. Intelligent drives offer significant advantages; because the controller is located within the drive itself, communication delays are eliminated therefore improving performance in automation and motion applications and removing the need for external controllers, saving panel space.

Energy Saving

It is estimated that energy saving of up to 20% can be achieved through installing and operating motors in a more efficient way. Installing Lenze AC Tech Variable Frequency Drives in certain applications such as fans and pumps can have a dramatic effect on the energy consumed. With motors consuming an estimated two thirds of electrical energy within industry, drives must form a key part of any programme to reduce carbon emissions.