Top Sellers

-

9767010116885

-

8 BZ-SS122079

-

DC-2154053

-

10262-FAIRCH147221

-

WEL-PHF-NN180247

-

ACO-51201R230370

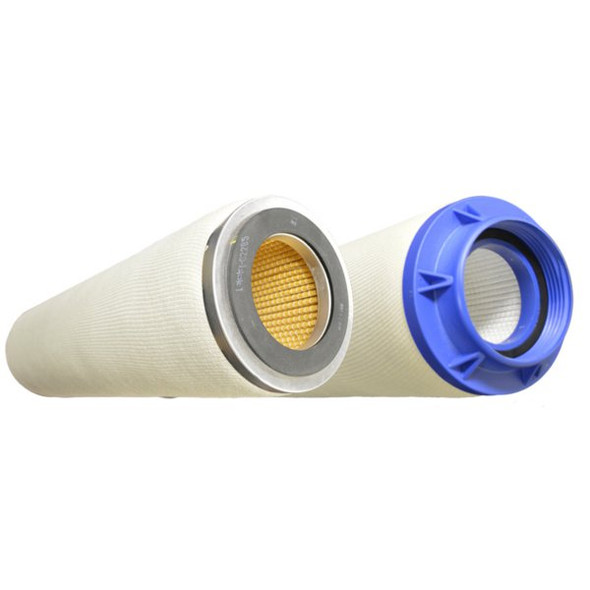

ACO-51201R Parker Velcon ACO Aquacon Series Water Absorbing Filter Cartridge ACO-51201RMSRP:Now:Was:/ Each

ACO-51201R Parker Velcon ACO Aquacon Series Water Absorbing Filter Cartridge ACO-51201RMSRP:Now:Was:/ Each -

NMO-150-P8-SS215610

NMO-150-P8-SS Cardinal Standard Mesh Liquid Filter Bag #8 NMO 150um NMO-150-P8-SSMSRP:Now:Was:/ Each

NMO-150-P8-SS Cardinal Standard Mesh Liquid Filter Bag #8 NMO 150um NMO-150-P8-SSMSRP:Now:Was:/ Each -

HK25-15154664

-

9696550116876

-

3 GAP GAUGE162222

-

PE-50-P2-S176116

-

CDF-220P251800

-

OS-51288172778

-

4 TZ-SS119368

-

9837078116133

-

PE-50-P12-S176114

-

2SC2-316118787

-

6-4 CBZ-SS121086

-

4 HP5ON-SS119329

-

6-4 FBZ-SS121096

-

9797624116883

-

1047T-N163581

-

DC-4154055

-

I-633C5TB172772

-

G-1541116857

-

NMO-75-P18X24-DS216179

NMO-75-P18X24-DS Cardinal Standard Mesh Liquid Filter Bag #18x24 NMO 75um NMO-75-P18X24-DSMSRP:Now:Was:/ Each

NMO-75-P18X24-DS Cardinal Standard Mesh Liquid Filter Bag #18x24 NMO 75um NMO-75-P18X24-DSMSRP:Now:Was:/ Each -

2002-3201249869

2002-3201 WAGO TOPJOB S Triple-Deck Terminal Block 2-Conductor 5.2mm - Gray 2002-3201MSRP:Now:Was:/ Each

2002-3201 WAGO TOPJOB S Triple-Deck Terminal Block 2-Conductor 5.2mm - Gray 2002-3201MSRP:Now:Was:/ Each -

PEM-600-P11-S220156

PEM-600-P11-S Cardinal Standard Mesh Liquid Filter Bag #11 PEM 600um PEM-600-P11-SMSRP:Now:Was:/ Each

PEM-600-P11-S Cardinal Standard Mesh Liquid Filter Bag #11 PEM 600um PEM-600-P11-SMSRP:Now:Was:/ Each -

71315SN2ENJ1N0H111C2121954

71315SN2ENJ1N0H111C2 Parker 7000 Series 3-Way General Purpose Solenoid Valve 1/4" NPT 71315SN2ENJ1N0H111C2MSRP:Now:Was:/ Each

71315SN2ENJ1N0H111C2 Parker 7000 Series 3-Way General Purpose Solenoid Valve 1/4" NPT 71315SN2ENJ1N0H111C2MSRP:Now:Was:/ Each -

12 PNBZ-SS117214