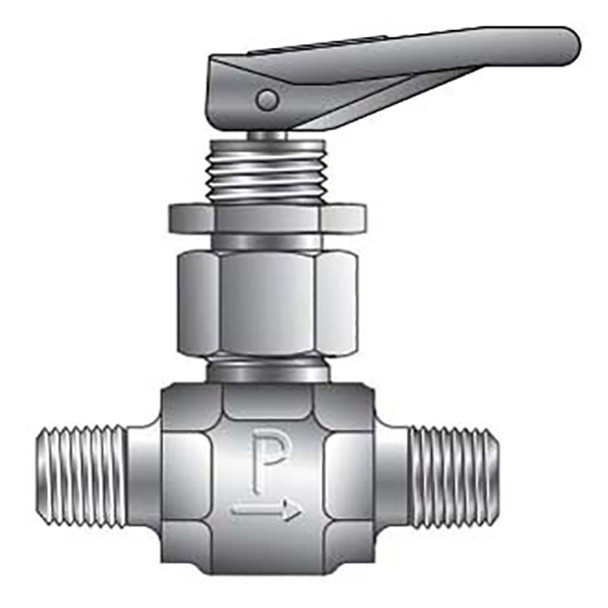

Image may represent a range of products. Product may vary based on listed specifications.

Parker Hannifin

Parker V6LQ Series Toggle Valve, 1/2" x 1/2", A-LOK Double Ferrule Compression x A-LOK Double Ferrule Compression, 300 PSIG CWP, F316 Stainless Steel, Highly Fluorinated Fluorocarbon Rubber Seal, 0.83 Cv, Panel Mount, In-Line, Toggle Valve.

- Manufacturer: Parker Hannifin

- LINKS_Browse All Parker Hannifin Products: /manufacturers/parker

- LINKS_Browse All VQ Series Products: /manufacturers/parker/vq-series

- DOCS_Parker VQ Series Needle Valve Installation Instructions: https://cdn11.bigcommerce.com/s-ca10qrhzok/content/documents/parker-vq-series-needle-valve-installation-instructions-ini-201-rev.pdf

- DOCS_Parker VQ Series Toggle Valves Datasheet: https://cdn11.bigcommerce.com/s-ca10qrhzok/content/documents/parker-vq-series-toggle-valves-catalog-pages.pdf

- Application: Purge/Rapid Fill System

- Body Material: ASTM A182 F316 Stainless Steel

- End Connection: A-LOK Double Ferrule Compr. x A-LOK Double Ferrule Compr.

- End To End Distance: 2.74 in.

- Handle Material: Nylon 6/6

- Nominal Size: 1/2 in. x 1/2 in.

- Pressure Rating: 300 psig CWP

- Temperature Rating: -20°F to 200 °F

- Product Family: VQ Series

- Product Category: Valves

- Product Type: Toggle Valves

- Brand/Division: Instrumentation Products

Frequently bought together: