Inductive Proximity Switch with Analog Output

Contrinex 12th Dec 2022

Why inductive?

Inductive proximity switches are highly popular with end-users, since they are

- robust

- cost effective

- insensitive to dirt

- standardized

- cost effective

- insensitive to dirt

- standardized

and therefore simple to use.

Why analog?

Classical (switching) inductive proximity switches in fact work internally as analog devices, although they produce a binary signal at the output, which is often desired. A large part of the available internal information, though, is lost. Switches with analog outputs provide the user with full information, permitting a variety of possible applications.

Previous technology

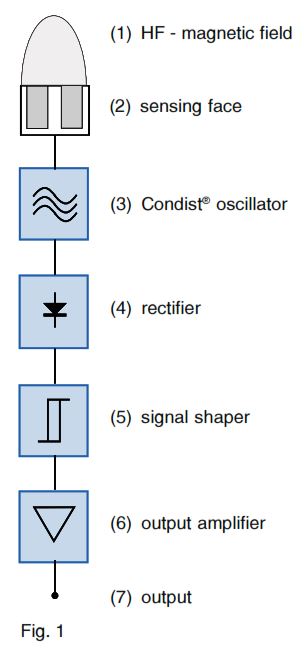

As mentioned above, proximity switches already work as analog devices. However, a signal shaper before the output stage changes the rectified analog oscillator signal into a digital one (Fig. 1). This signal shaper also exists in switches with analog outputs, but there it serves an entirely different purpose. Instead of producing a switching point, it converts the signal emitted by the rectifier (4) into a more usable, but still analog, form. Its main purpose is the generation of defined starting and end points of the output function, as well as a defined flow in between. Such switches have been available on the market for some time. The scope of their application has, however, so far remained very small, principally due to severe limitations of their usable sensing range.

New technology

To a large extent, the new switch presented here works in a similar way to the well-known switching versions. The essential difference lies in the type of oscillator (3). Instead of conventional technology, a Condist oscillator, of completely different design, is used. CONTRINEX has already been using this oscillator for a number of years in the large scale manufacture of proximity switches with long operating distances. As a result, a much larger sensing range is obtained, with excellent stability and repeat accuracy. Since intermediate digitization has been dispensed with, the switch resolution is furthermore virtually unlimited.

Advantages of the new proximity switch

- Very large sensing range

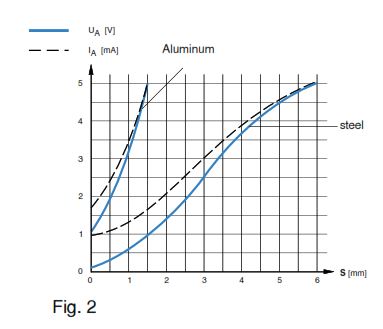

- Available in an economical non-linearized execution with favorable transfer function (Fig. 2) and in linearized execution (in preparation)

- Low specimen scattering

- Short design

- Current and voltage output in the same switch

- Available in an economical non-linearized execution with favorable transfer function (Fig. 2) and in linearized execution (in preparation)

- Low specimen scattering

- Short design

- Current and voltage output in the same switch

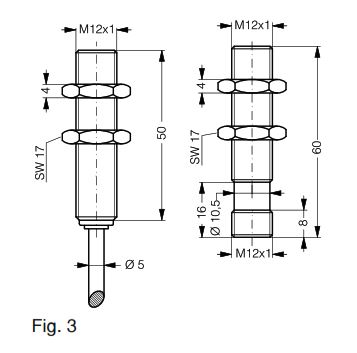

At present, the switches are available in the size M12 (Fig. 3) series. Further sizes are in preparation.

Applications

- Proximity switches with multiple switching points:

The output signal is transmitted to the analog input of a PLC. Any number of switching points can then be produced by means of software. Another possibility would be to employ a suitable analog switching device with multiple switching points.

- Start-up control

The classical procedure consists of simply turning the drive off after it has passed an end-point (detected, for instance, by a binary proximity switch). The end-point position is, however, relatively uncertain, due to the uncontrolled mechanical run-out. By using an analog output proximity "switch" with, for example, a PLC, a highly accurate start-up control can be achieved at little cost.

- Non-contact potentiometer

The use of a standard contact potentiometer for the detection of mechanical values (e.g. pedal position in vehicles) is frequently unsatisfactory. Vibrations, environmental influences, wear, etc. lead to unacceptably high maintenance costs and reliability problems. In these cases, use of the new proximity switch fundamentally improves the situation, without incurring a high investment cost. Conversion of mechanical movement, e.g. turning, into a form suitable for the proximity switch, can be carried out by means of eccentric disks, wedges, etc. If necessary, switches can be supplied to customer specifications.

- Self-teaching function

The mechanical adjustment of proximity switches in the plant is a well-known, and until now, inevitable installation problem, requiring reliable personnel and time. The problem is greater still when installing a spare part in the field. The use of an analog output proximity "switch" offers an elegant possibility of overcoming this problem. In effect, the switch is positioned only approximately, e.g. on the basis of a marker. Next, the PLC causes the target object to move mechanically to the desired switching position, determines the corresponding output signal of the proximity "switch", and stores the value as a future switching point.

- Concentricity monitoring

Accurate concentricity of rotating machine parts is a prerequisite for trouble-free operation and long life. Concentricity can deteriorate unpredictably with time, e.g. due to bearing wear, and this consequently leads to unexpected and often catastrophic breakdowns, incurring expensive repairs and downtime. On cost grounds, the installation of available concentricity monitoring devices is frequently avoided. In such cases, an analog output proximity "switch", together with a PLC, frequently already installed, provides a simple, economical, and very efficient solution.

- Vibration monitoring

Vibration can also be an indication of a machine's condition. Amplitude monitoring over time allows preventive maintenance to be carried out, and so helps to avoid unexpected and often catastrophic breakdowns with the ensuing expensive repairs and downtime. Here also, an analog output proximity "switch", together with a PLC, frequently already installed, offers a simple, economical and, in many cases, adequate solution.

Cost comparison

To a great extent, the non-linearized switch is assembled from the same parts as the corresponding switching device. Additionally, end point trimming is basically not more expensive. This results in an economically interesting cost situation, since the switch presented here (non-linearized execution) is only about 20% more expensive than the corresponding switching device.

12th Dec 2022