Three Different Technologies

Contrinex 12th Dec 2022

Three Different Technologies

Contrinex inductive devices work according to one of three different technologies. All involve the generation of an alternating magnetic field that emerges at the sensing face. The presence of a conductive, generally metallic, object influences this field in a way that can be detected and evaluated by built-in electronics. All Contrinex ASIC sensors are IO-Link enabled in PNP NO versions.

TECHNOLOGY FAMILIES

CLASSICS FAMILY: Conventional technology, engineered by Contrinex

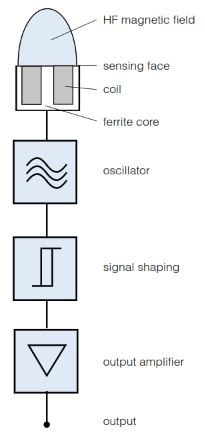

Fig. 1: Conventional inductive sensor technology, as used in the Classics family

The Classics family uses conventional inductive sensor technology, but with the benefit of a Contrinex ASIC (application specific integrated circuit). ASIC technology ensures reliability, stability and ease of commissioning, due to low variation. Sensors in this family achieve operating distances up to 2 x the industry standard. All ASIC sensors in the Classics family are IO-Link enabled in PNP NO versions.

Classics sensors have a conventional oscillator and coil generating a high-frequency magnetic field that emerges at the sensing face. Any metallic object found in this field absorbs some of the energy, which is in turn detected and evaluated by built-in electronics (Fig. 1).

Ferromagnetic metals (steel, nickel, cobalt) absorb the most energy. The achievable operating distances are therefore greatest with these metals. Non-ferromagnetic metals, such as aluminum, absorb less energy. As a result, operating distances are lower (approx. 25 ... 45% of those on steel).

The Classics technology family (series 600) includes devices from the ranges Basic, Miniature, Extra Pressure, Extra Temperature, High Temperature, Wash-down and 2-Wire.

EXTRA DISTANCE FAMILY:

Increased stability for exceptionally long operating distance

The Extra Distance family is based on the Condist oscillator developed by Contrinex. Sensors benefit from up to 4x the standard operating distance, keeping them out of harm’s way in rugged, industrial environments. Sensor lifetime is therefore increased.

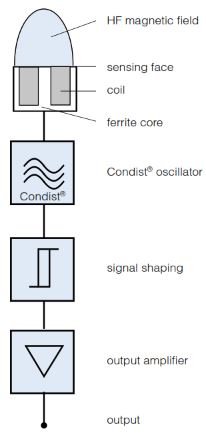

Fig. 2: Contrinex’s Condist inductive sensor technology, as used in the Extra Distance family

Like Classics family sensors, these also generate a high-frequency magnetic field that emerges at the sensing face (Fig. 2). Again, the resulting effect is that any metallic object entering the field absorbs energy from it.

However, the oscillator and the subsequent signal evaluation circuit are completely different, with the objective of achieving a significantly better stability with respect to environmental influences, in particular temperature. The most important contribution to this comes from the Contrinex Condist oscillator.

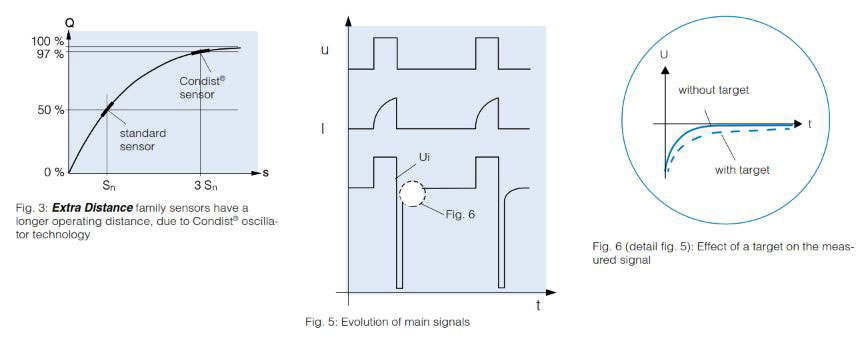

Improved stability permits the switch point to be further away, leading to long operating distances on ferromagnetic metals (Fig. 3). Sensors with this technology also react particularly well to narrow targets, e.g. small screws, wires and foils.

Apart from the Condist oscillator, all other assemblies are equivalent to the Classics family. Material dependencies and other properties are also the same as for Classics family sensors.

Special attention has been paid to meet the relevant standards as much as possible, so that easy interchangeability with conventional devices is guaranteed. Great emphasis has been placed on very good EMC resistance and on perfect sealing against liquid penetration. The Extra Distance technology family includes devices from the Basic, Miniature, Extra Pressure, High Pressure and Analog Output ranges. This technology is used in series 500 devices.

FULL INOX FAMILY:

All-round stainless steel protection - practically indestructible

The Full Inox family is based on Contrinex’s patented Condet technology. These one-piece stainless steel sensors are not only the most durable on the market, they also offer long operating distances on any conductive metal.

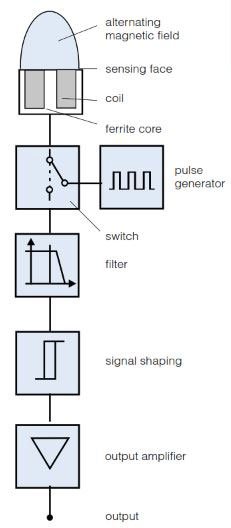

Full Inox sensors also function according to inductive technology. However, the coil which generates the magnetic field is not part of the oscillator (Fig. 4). Instead, the field is generated by periodic, short transmitter current pulses, which flow through the coil (Fig. 5). This field induces a voltage in the target which, in turn, generates a current flow in it. When the transmitter current pulse is switched off, the current in the object dies away, causing a voltage to be induced in the transmitting coil (Fig. 6).

This voltage generates the signal required, and is in principle independent of the field’s energy loss. Therein lies the fundamental advantage of this technology, since the field energy losses, which conventional devices is guaranteed. Great emphasis has been placed on very good EMC resistance and on perfect sealing are evaluated in conventional sensors, are subject to a number of undesirable environmental and material influences. Condet technology allows the sensor, including its face, to be fully encapsulated in a protective, stainless steel housing, with the added security of long operating distances.

The coupling between the target and the coil is rather like a transformer, and is hence temperature independent and only slightly influenced by the target’s material. Operating distances are therefore identical on steel and aluminum. Only metals which are non-ferromagnetic and also have poor electrical conductivity give a reduced usable signal.

The Full Inox family includes devices from the Basic, Miniature, Extreme, High Pressure, Washdown, Weld-Immune, Chip-Immune, Maritime and Double-Sheet ranges.

12th Dec 2022